Here’s a list of best Artificial Kitchen Stones available in Pune:

- Corian

- Solid Surfaces

- Quartz

- Artificial Stone

- Porcelain Slabs

- Nano White

- Sintered Stone

- Vinyl

- Epoxy

The Indian design and construction industry has seen a significant shift from natural materials to artificial stones, particularly in kitchen countertops.

Especially in cities like Pune, where functionality plays a significant role in kitchens, artificial kitchen stones are becoming an increasingly popular choice due to their aesthetic appeal and practicality.

Price List of Artificial Kitchen Stones Available in Pune

| S. No. | Name of the Material | Image | Price with Installation (INR per sq. ft.) approx. | Chat Link | Get Exact Price |

|---|---|---|---|---|---|

| 1. | Corian |  | ₹1,500+ per sq. ft. | Chat Now | Exact Price |

| 2. | Solid Surfaces |  | ₹350 to ₹1,500+ per sq. ft. | Chat Now | Exact Price |

| 3. | Quartz |  | ₹850 to ₹2,000 per sq. ft. | Chat Now | Exact Price |

| 4. | Artificial Stone |  | Varies based on the type and grade | Chat Now | Exact Price |

| 5. | Porcelain Slabs |  | ₹700 to ₹1,600 per sq. ft. | Chat Now | Exact Price |

| 6. | Nano White |  | ₹2,400 to ₹3,400 per sq. ft. | Chat Now | Exact Price |

| 7. | Sintered Stone |  | ₹2,000 to ₹4,000+ per sq. ft. | Chat Now | Exact Price |

| 8. | Vinyl |  | ₹280 to ₹500 per sq. ft. | Chat Now | Exact Price |

| 9. | Epoxy |  | ₹450 to ₹900 per sq. ft. | Chat Now | Exact Price |

In this blog post , we examine the top artificial kitchen stones, understand their properties, pros, and cons, and explore their best prices in Pune.

- Price List of Artificial Kitchen Stones Available in Pune

- Top 9 Artificial Kitchen Stone Options

- 1. Corian

- 2. Solid Surfaces

- 3. Quartz

- 4. Artificial Stone

- 5. Porcelain Slabs

- 6. Nano White

- 7. Sintered Stone

- 8. Vinyl

- 9. Epoxy

- What is Driving the Shift Towards Artificial Stone?

- Comparative Analysis of Artificial Stone Counters

- Natural Stone vs Artificial Stone

- Price List of Artificial Kitchen Stones Available in Pune

- Real-World Performance Test for Indian Kitchens

- Where and How to Find the Right Person to Install Artificial Stone?

- Pro-Tips to Select Artificial Countertop Stone

- Picking the Most Suitable Match

Top 9 Artificial Kitchen Stone Options

1. Corian

Corian countertops are one of the most aesthetic artificial stone choices, resembling the sophisticated look of marble and granite. These comprise primarily of plastic polymers and stone derivatives.

In terms of visual appeal, Corian offers a much more uniform look than natural granite or marble. It is an excellent choice for kitchens demanding consistency in terms of the look. Furthermore, Corian offers a wide range of colours, ranging from deep black to natural beige and white.

Pros and Cons

| Pros | Cons |

| Wide range of tones, mimicking granite and marble while keeping the pattern consistent throughout the span and thickness. | Not suitable for kitchens with heavy cooking, as these aren’t scratch-resistant. Daily wear may lead to permanent scratches. |

| A 20mm thick slab is priced at INR 250 per sq.ft., however, the final price varies based on customisation, selection, and installation. | Can’t withstand direct contact with hot utensils, as it may lead to permanent damage to the surface. |

| Stain-resistant to an extent. | Prolonged exposure to harsh cleaning agents like bleach may lead to discolouration. |

| Simple upkeep, as it can be cleaned with soap and water. | |

| Can be installed with minimal wastage as the slabs are available pre-designed and cut. |

Final Verdict for Corian

While Corian is an excellent material in terms of aesthetics and stain resistance, it may not work as a countertop for Indian kitchens following heavy cooking. Rather, its modern aesthetics make it an ideal choice for kitchens with controlled usage, preparation kitchen islands, and decorative backsplash for surfaces with minimal contact with hot utensils and sharp knives.

2. Solid Surfaces

Solid surfaces are synthetic slabs, too, made with a blend of polyester materials, natural stone dust, and synthetic acrylic. As these slabs can be custom-made, it offers the flexibility to integrate sinks into them while moulding.

While their composition is almost similar to that of Corian, these often lack brand assurance. Solid surfaces are available in a wide variety of tones and patterns, ranging from solid colours to granite-resembling patterns.

Pros and Cons

| Pros | Cons |

| Budget-friendly, with the average cost of a sheet starting at INR 300 per sq. ft. | Can scratch easily if abrasive kitchen tools come in contact. |

| The seamless and non-porous surface makes it a hygienic choice. | May exhibit scorching if kept in contact with hot utensils for a long time. |

| Complements modern aesthetics. | It is a fairly soft material, wherein the edges remain prone to chipping. |

| Demands minimal maintenance to keep up with the aesthetics. Scratches can be buffed out with sandpaper. |

Final Verdict for Solid Surfaces

Solid surfaces can be used for pantry slabs with careful usage of heat. For traditional Indian kitchens following high-heat cooking, other materials like quartz or granite may function better.

3. Quartz

Quartz is one of the most popular, durable, and low-maintenance artificial stones for kitchens. It is engineered with a blend of natural quartz, polymers, and binders shaped to form slabs. When it comes to the tones and patterns, there’s no limit, as the desired tones can be engineered.

It has become a predominantly adopted material, especially in fast-paced cities like Pune. The urban flats prefer quartz due to minimal maintenance demands and pleasing aesthetics.

Pros and Cons

| Pros | Cons |

| Available in a plethora of colours and designs. | Can’t be used for outdoor kitchens as direct exposure to high temperatures, sunlight, and extreme weather conditions can degrade the surface. |

| The price of the slab starts at INR 195 per sq.ft. | May get damaged with extremely hot utensils, as it can withstand heat up to 300°F. |

| Extremely durable, enabling it to withstand daily wear without scratching. | Demands skilled experts for seamless installation. |

| Exhibit high stain resistance. | |

| Easier handling as these slabs are not brittle, hence, cutting, processing, and installation are convenient. |

Final Verdict for Quartz

If you’re looking for low-maintenance and highly durable materials for indoor kitchens, quartz can be one of the choices. The wide range of tones allows you to pick the most complementary tone and pattern.

However, if you’re looking for a material for an outdoor countertop, you may consider opting for other durable materials like granite and concrete.

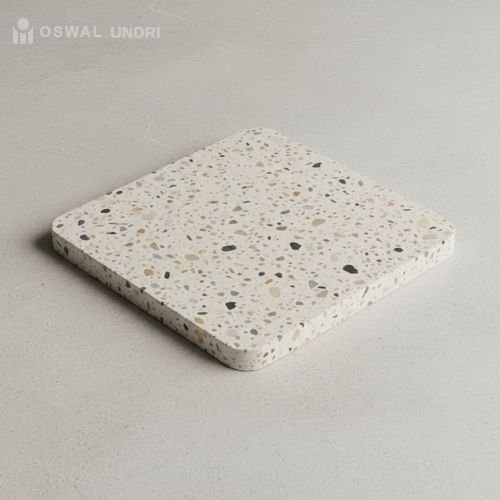

4. Artificial Stone

As the name suggests, artificial stones visually mimic the natural stones from which they are derived. For example, an artificial granite is engineered with fine granite dust and resins.

Primarily, these are more stylish and affordable alternatives to natural stone.

Pros and Cons

| Pros | Cons |

| Offers a consistent look throughout its span. | A few of the artificial stones may scratch in Indian Kitchens due to direct chopping on the countertops. |

| Highly resistant to stains due to its non-porous nature. | Not all artificial stones withstand high temperatures. |

| Usually, artificial stones are less expensive than natural stones. | Doesn’t perform well in outdoor kitchens. |

| Comparatively, artificial stones demand minimal maintenance. |

Final Verdict for Artificial Stone

Artificial stones are known to introduce a stylish edge to the kitchens. However, there has to be a strategic balance of aesthetics and practicality in Indian kitchens. These stones work well for moderate-usage kitchens, secondary cooking areas, and pantry counters.

In order to install it in Indian kitchens, make sure to opt for high-grade and promising quality stones from a reliable supplier.

5. Porcelain Slabs

Porcelain slabs in kitchen countertops are prized for their unmatched durability, aesthetics, stain resistance, and low maintenance. These factory-made slabs exhibit uniform composition throughout their length and thickness.

They are often considered one of the best alternatives to natural stone countertops, imitating the look of natural stone.

Pros and Cons

| Pros | Cons |

| Available in designs to imitate natural stones. | Demands professional installation for precision and perfection. |

| Extremely affordable, with the slab price starting at INR 120 per sq. ft. | Low-grade slabs may exhibit chipping at the edges. |

| Highly resistant to heat, stains, and scratches. | For enhanced performance, it has to be sourced from brands promising high quality. |

| Incredibly low-maintenance materials work well without sealing and demanding simple cleaning with soap and a soft cloth. | |

| Highly UV-resistant, making it ideal for outdoor applications as well. |

Final Verdict for Porcelain Slabs

Undoubtedly, porcelain slabs are one of the best replacements for natural stone counters. Whether you’re looking for countertop material for an indoor or outdoor kitchen, porcelain slab is both a practical and aesthetic choice.

The key point to keep in mind while selecting the slab is to opt for a high-grade material. Make sure to work with a reputable brand for promising quality.

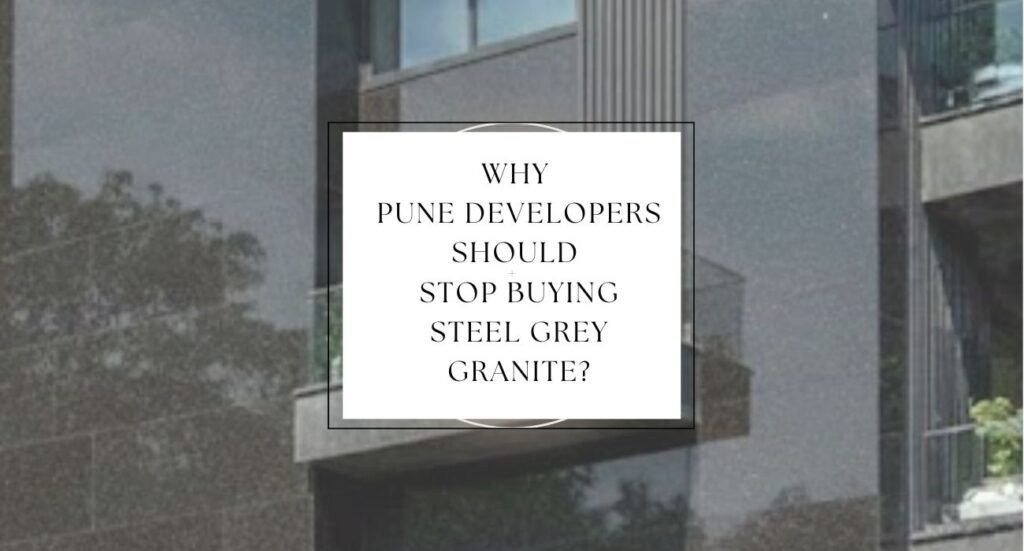

6. Nano White

Nano White is an engineered glass-based stone, which, due to its allure, is often mistaken for natural stone. This synthetic stone comprises resin, minerals, and glass.

As the name suggests, it’s white in colour with consistency in its texture and tone throughout the slab. Nano white slabs offer a modern edge to the interiors owing to their flawless visual appeal. It is often graded based on the finish, quality, and translucency, categorised as G5, G7, and G9, with G9 being the most premium grade.

Pros and Cons

| Pros | Cons |

| Amps up the aesthetics with its bright white tone. | Is slightly more expensive than the other alternatives, with a starting price of INR 450 per sq. ft., but the installation cost is higher. |

| Offers good heat and stain resistance. | May crack under pressure. |

| Highly resistant to heat, stains, and scratches. | The original and high-quality Nano White is only available in white colour. |

Final Verdict for Nano White

When it comes to replacing natural stone with an alternative, Nano White may not be the best choice due to its brittle nature and super-white colour. In the Indian context, it is not suitable for kitchens used for heavy cooking.

However, if white suits your palette, you can consider installing G5 for its budget-friendly cost, ranging between INR 320 and INR 380 per sq. ft. Consider adding it to the low-usage slabs or decorative islands.

7. Sintered Stone

Sintered stone is one of the innovative stones manufactured with a blend of recycled glass, porcelain, quartz, and granite. As it uses heat and pressure for the binding of these materials, it is one of the most durable and non-porous materials.

This artificial stone is known for its organic appearance as it exhibits variations in the patterns to mimic the look of natural stone.

Pros and Cons

| Pros | Cons |

| A wide range of patterns resembling the aesthetics of concrete counters to marble. | These are often priced higher, with the premium finishes ranging between INR 550 and INR 850 per sq. ft. |

| Withstands the daily wear of busy kitchens, exhibits exceptional durability, UV resistance, and scratch resistance. | The chipped or cracked slabs can’t be repaired. Rather, the entire slab has to be replaced. |

| A hygienic choice as the manufacturing doesn’t involve harmful chemicals, and it resists bacterial and mould growth. | |

| No cracks or discolouration of the surface, even when in contact with pots straight from the stove. |

Final Verdict for Sintered Stone

Sintered stone is one of the premium choices for kitchen countertops. For Indian kitchens following heavy cooking with chances of oil spillage, stains from spices, and where hot vessels are often directly placed on the slabs, sintered stone outshines the other materials.

While it has high upfront costs, its tough structure and low maintenance demands make it a cost-effective choice in the long run.

8. Vinyl

Vinyl countertops are made from PVC-based sheets or tiles that are laminated over MDF, plywood, or existing countertop surfaces. They imitate natural stone, wood, or solid colours and are preferred in budget makeovers and rental homes. The material combines plastic resins, stabilisers, and decorative films, creating a lightweight and visually appealing alternative to stone.

Vinyl countertops are popular for their uniform finish, variety of design options, and ease of installation. They provide a modern visual upgrade without structural renovation. Quality varies based on film thickness, wear layer, and backing material, and they are informally categorised as economy, standard, and premium grades depending on durability and scratch resistance.

Pros and Cons

| Pros | Cons |

|---|---|

| Amps up interiors with realistic marble and wood-look designs | Prone to scratches and cuts from knives and sharp utensils |

| Very affordable, starting around ₹180–₹300 per sq. ft. | Limited heat resistance — hot vessels can leave burn marks |

| Water-resistant surface, suitable for dry and semi-wet areas | Outer film may peel or bubble with prolonged water exposure |

| Comfortable and slightly soft to the touch | Can look “artificial” compared to natural or engineered stone |

| Easy to install and replace without heavy construction | — |

Final Verdict for Vinyl

Vinyl countertops are an excellent choice for budget renovations, rental properties, or secondary kitchens. They provide a smart visual upgrade without large investment.

However, they are not recommended for heavy-duty Indian kitchens involving high heat and frequent chopping.

9. Epoxy

Epoxy countertops are created by coating an existing surface, such as granite, marble, tile, or concrete—with a layer of two-part epoxy resin. Once cured, it forms a seamless, glossy, glass-like surface that dramatically refreshes interiors. Epoxy is valued for its customisable designs, including marble effects, metallic swirls, and solid shades.

Because it is applied on-site as a liquid, epoxy delivers a joint-free finish and is commonly used to refurbish old countertops instead of replacing them. Performance depends strongly on the quality of resin and application skill, making professional installation essential.

Pros and Cons

| Pros | Cons |

|---|---|

| Creates a high-gloss, premium aesthetic similar to luxury stone | May crack or chip under impact or slab movement |

| Highly resistant to stains and household chemicals | Heat resistance is moderate — hot pans can damage the surface |

| Can be applied over existing countertops — no demolition required | Quality depends heavily on installer expertise |

| Allows unique custom designs and colours | Inferior epoxy may yellow in sunlight over time |

| Suitable for restoring worn or dated slabs | Emits odour during installation and requires curing time |

Final Verdict for Epoxy

Epoxy countertops work exceptionally well for homeowners who want to upgrade the look of their kitchen without replacing the base countertop. They provide a luxury finish at a relatively affordable cost.

But, due to moderate heat tolerance and potential brittleness, epoxy countertops are not ideal for very heavy Indian cooking environments.

What is Driving the Shift Towards Artificial Stone?

Let’s first understand why there has been a shift from natural stone to engineered stone.

Enhanced Aesthetics

As artificial stones are manufactured, they offer better consistency in terms of their visual appeal. Whereas natural stones are inconsistent due to the varying geological formations.

When it comes to kitchen stones, uniformity in design is often desired owing to the span of slabs. This is why homeowners prefer engineered stones for consistent colour, pattern, and finish.

Better Durability

One of the primary reasons for the switch towards artificial stones is the exceptional durability. As compared to the porous natural stones, engineered stones like quartz offer higher stain resistance.

Artificial stones are an ideal choice for countertops with heavy usage; their resilience minimises the chances of chipping and cracking.

Varied Colours

When it comes to the colours of countertops, artificial kitchen stones like Corian and quartz offer a wide spectrum with solid tones or patterned surfaces.

As compared to natural stones, artificial stones offer more colours at a comparatively lower cost. Another benefit of selecting artificial stones is the clarity of the budget. While the prices of natural stones may vary based on the availability, selection, and wastage, artificial stones are often transparently priced for informed budget planning.

Low Porosity

Engineered stone slabs exhibit lower porosity than natural stones. These surfaces are naturally resistant to microbial growth, like mould and bacteria. Hence, they’re often picked as hygienic solutions for the kitchen.

Minimal Maintenance

With artificial kitchen slabs, you don’t have to go through the hassle of sealing the surface periodically. Rather, these demand minimal maintenance.

Simply cleaning the slabs with warm water and a mild soap solution does the job to keep them clean.

Comparative Analysis of Artificial Stone Counters

| Material | Compatible Style / Applications | Hardness (Mohs) | Scratch Resistance | Stain Resistance | Heat Resistance |

|---|---|---|---|---|---|

Corian (Acrylic Solid Surface) | Modern, minimalist, seamless designer kitchens | 2–3 | Low – scratches easily with utensils or knives | Good | Very low |

Solid Surfaces (General Acrylic/Poly) | Contemporary, minimalist designs | 2–3 | Prone to surface wear | Good | Very low |

Quartz | Modern luxury kitchens | 7 | High | Excellent | Heat-resistant up to a limit (trivets recommended) |

Artificial Stone (engineered/low-grade composites) | Budget modern or traditional kitchens | ~7 | Moderate – depends on slab grade | Moderate | Varies by composition |

Porcelain / Ceramic Slabs | Modern & traditional; indoor/outdoor kitchens | 7–8 | High | Excellent | High |

Nano White (Engineered glass-based) | Decorative kitchens; crisp white aesthetics | 6–7 | Moderate – may develop scratches | Good | Heat-resistant but structurally brittle |

Sintered Stone (Dekton-type) | Luxury, high-performance kitchens | 6–8 | Highly scratch-resistant | Excellent | Excellent – withstands direct hot vessels |

Vinyl Countertops (PVC laminate surfaces) | Budget kitchens, rental homes, light-use counters | 2 | Low–Moderate; scratches and cuts show easily | Good for everyday spills | Very low – hot pans cause bubbling/burns |

Epoxy Countertops (poured resin coating) | Show kitchens, bars, decorative islands, refurbishments | 2–3 | Moderate – may chip/crack on impact | High – excellent chemical resistance when cured | Moderate – hot vessels can damage/yellow surface |

Natural Stone vs Artificial Stone

| Property | Natural Stone | Artificial Stone |

| Composition and Source | Quarried from nature | Factory-engineered |

| Visual Appeal | Each slab varies with each variation in texture, colour, and veining. | As the slabs are engineered, they have a consistent colour and pattern. |

| Durability | Extremely durable. | Varies based on the type of stone. For example, Corian is brittle while porcelain is durable. |

| Porosity | Not all natural stones promise low porosity. For example, marble is porous. Demands sealant application. | Most of the engineered stones are known for their minimal porosity. |

| Hygiene | Comparatively less hygienic due to the involvement of chemicals in sealing. | Hygienic alternative. |

| Availability | A few of the natural stones may not be available widely due to their rarity. | Can be easily sourced. |

Price List of Artificial Kitchen Stones Available in Pune

| S. No. | Name of the Material | Image | Price with Installation (INR per sq. ft.) approx. | Chat Link | Get Exact Price |

|---|---|---|---|---|---|

| 1. | Corian |  | ₹1,500+ per sq. ft. | Chat Now | Exact Price |

| 2. | Solid Surfaces |  | ₹350 to ₹1,500+ per sq. ft. | Chat Now | Exact Price |

| 3. | Quartz |  | ₹850 to ₹2,000 per sq. ft. | Chat Now | Exact Price |

| 4. | Artificial Stone |  | Varies based on the type and grade | Chat Now | Exact Price |

| 5. | Porcelain Slabs |  | ₹700 to ₹1,600 per sq. ft. | Chat Now | Exact Price |

| 6. | Nano White |  | ₹2,400 to ₹3,400 per sq. ft. | Chat Now | Exact Price |

| 7. | Sintered Stone |  | ₹2,000 to ₹4,000+ per sq. ft. | Chat Now | Exact Price |

| 8. | Vinyl |  | ₹280 to ₹500 per sq. ft. | Chat Now | Exact Price |

| 9. | Epoxy |  | ₹450 to ₹900 per sq. ft. | Chat Now | Exact Price |

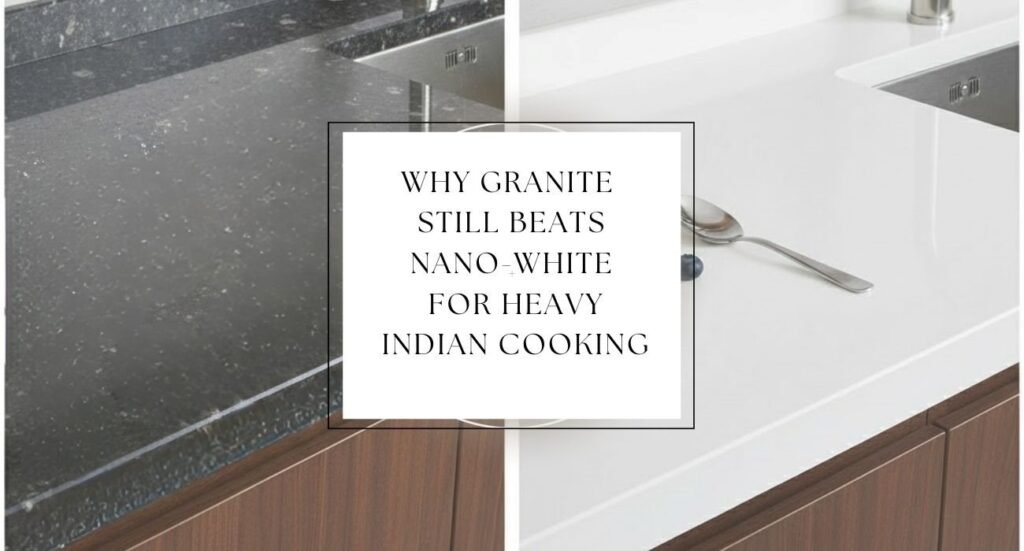

Real-World Performance Test for Indian Kitchens

Indian cooking involves extensive usage of oils, spices, turmeric, lemon juice, etc., and a direct impact of hot utensils on the kitchen countertops. And these are the extreme conditions under which the kitchen slab may or may not perform well.

Let’s unveil the best-performing artificial stones under the key performance tests.

1. Stain Resistance Test

The tests conducted on these artificial stones with common staining agents like turmeric, coffee, and pickle oil revealed that Corian and solid surfaces are more prone to staining.

While other surfaces like quartz, porcelain slabs, and sintered stone could be cleaned easily with a wet cloth, Corian and solid surfaces were left with a yellow turmeric stain that had to be cleaned with acetone.

A key consideration to keep in mind is that harsh chemicals often lead to the abrasion of Corian slabs and solid surfaces. Hence, these don’t work very well in kitchens using staining agents in their cooking.

2. Knife Scratch Test

Several Indian kitchens don’t prefer the use of chopping boards. Kitchen countertops are often used for direct chopping of fruits and vegetables.

In this test, both sintered stone and porcelain slabs stood out in durability.

Here’s the order of durability amongst these materials, ranging from the highest to the lowest:

- Sintered Stone / Porcelain Slabs

- Artificial Stones (depends on grade and brand)

- Quartz

- Nano White (engineered glass-based, strong but brittle)

- Epoxy Countertops

- Corian and Other Solid Surfaces (acrylic-based)

- Vinyl Countertops

Where and How to Find the Right Person to Install Artificial Stone?

Choosing the right installer for artificial stone is essential because workmanship directly affects durability and appearance. Start by asking the stone brand or dealer for authorised or certified installers, especially for quartz, sintered stone, or porcelain slabs. You can also approach local fabrication workshops and seek recommendations from architects and interior designers. Review past projects and avoid choosing purely on price. A skilled installer will manage measurements, transport, cut-outs, seams, and edge finishing. Prioritise experience, certification, proper tools, and references to ensure your artificial stone is installed safely and performs well for years.

What to check before finalising

- Portfolio and site photos

- Written quotation and timeline

- Experience with your specific material

- Measurement and templating process

Where to find installers

- Brand-authorised installer lists

- Local fabrication workshops

- Architects and interior designers’ referrals

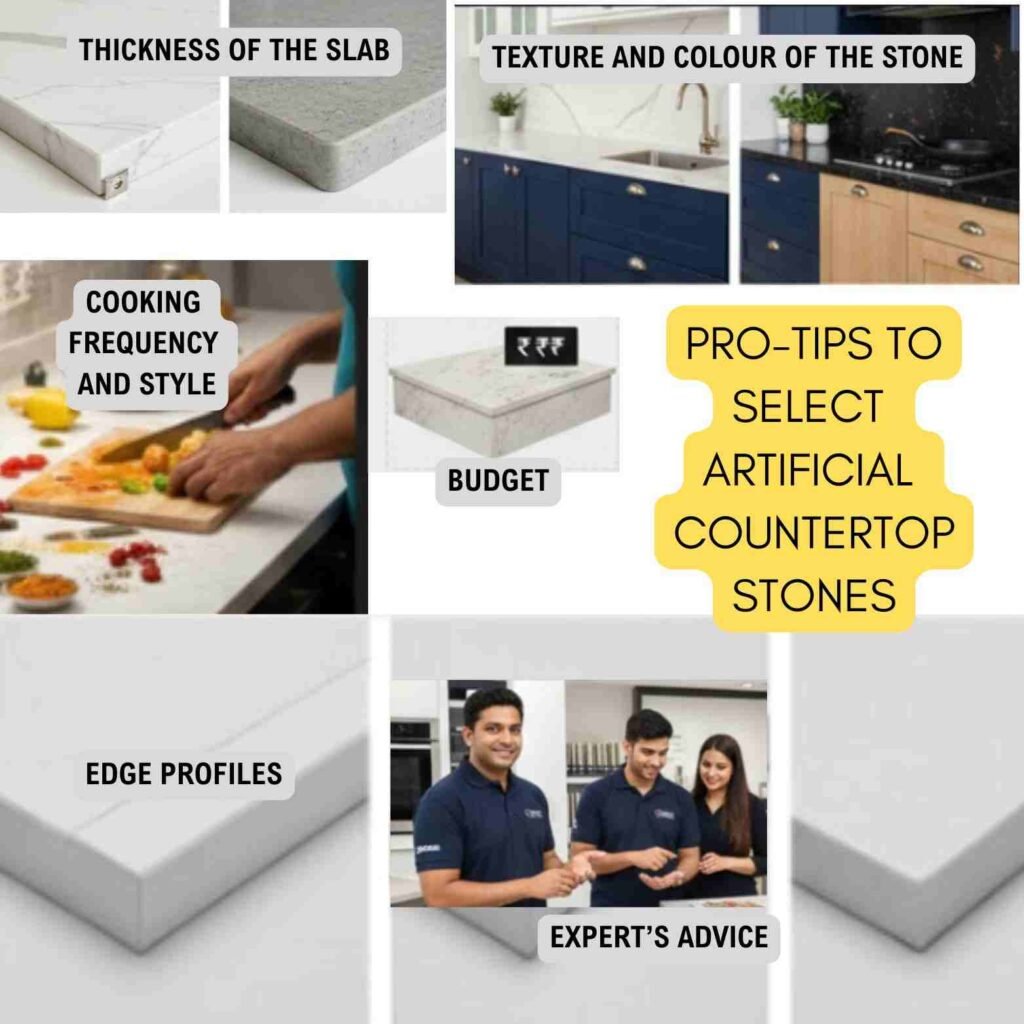

Pro-Tips to Select Artificial Countertop Stone

Thickness of the Slab

If you wish to install sleek slabs, sintered stone with an even 12mm thickness can offer durability. On the other hand, materials like quartz and porcelain can be installed in higher thicknesses, like 15mm or 20mm, for high performance.

Texture and Colour of the Stone

Look around and understand the aesthetics of the kitchen. Based on the tones of kitchen cabinets, pick either a complementary or contrasting stone colour to enhance the aesthetics of the kitchen.

Cooking Frequency and Style

Not every artificial stone is made to withstand the heavy Indian cooking habits. Make sure to be clear on the cooking frequency and style to make an informed decision.

Budget

While porcelain slabs are affordable, sintered stone, on the other hand, may prove to be extremely high-end. Analyse the cost of different artificial stones before finalising a budgeted choice.

Edging

Edge profiles often define the aesthetics of the kitchens, with designs ranging from simple edges to the traditional ogee profiles. The thickness of these edges is based on the overall slab thickness.

For more children and family-friendly kitchens, consider opting for bullnose edging for enhanced safety.

Expert’s Advice

If you’re confused about different types of artificial stones and what may work well for your kitchen habits, consider the idea of consulting an expert. At Oswal Granites, our team of skilled experts understand your requirements and offers you the best options with promising durability.

Picking the Most Suitable Match

Now that you’ve understood different properties, price range, and real-world performance of different artificial stones for kitchen countertops, make an informed decision.

Always begin by analysing your family’s kitchen habits, budget, and assessing what the design demands– whether you need a solid surface or a material mimicking the natural stone. At the same time, don’t rule out the maintenance requirements in the long run.

For budgeted countertops, you can opt for either porcelain or quartz, as both come at a reasonable price range. If you’re aiming for a statement countertop with high longevity, consider picking sintered stone as a replacement for the natural stone counters.

To fulfil the aesthetic demands of a bright white kitchen, consider adding Nano white; however, be mindful of its grade and maintenance, as it is a brittle material. For counters with minimal usage, you may add either solid surfaces or Corian.

Still confused about the best artificial stone that will fit your kitchen? Connect with our stone experts today.

Key Takeaways

- Sintered Stone & Porcelain Slabs lead in durability – These are the only artificial materials that reliably withstand direct heat from hot woks and resist scratches from direct knife contact, essential for heavy Indian cooking.

- Quartz remains the most balanced choice – Offering a massive range of designs starting at ₹850 per sq. ft. (installed), quartz provides excellent stain resistance, though it requires trivets for extremely hot utensils.

- Aesthetic vs. Utility Divide – Materials like Corian, Nano White, and Solid Surfaces are visually stunning for modern “prep kitchens” or islands but are too brittle or heat-sensitive for primary cooking areas.

- Installation is as vital as Material – Because artificial stones are engineered, they require specialized tools and color-matched epoxy resins for seamless joints; hiring a brand-certified installer is highly recommended.

Get a free consultation, expert guidance, and a detailed quote tailored to your project needs.