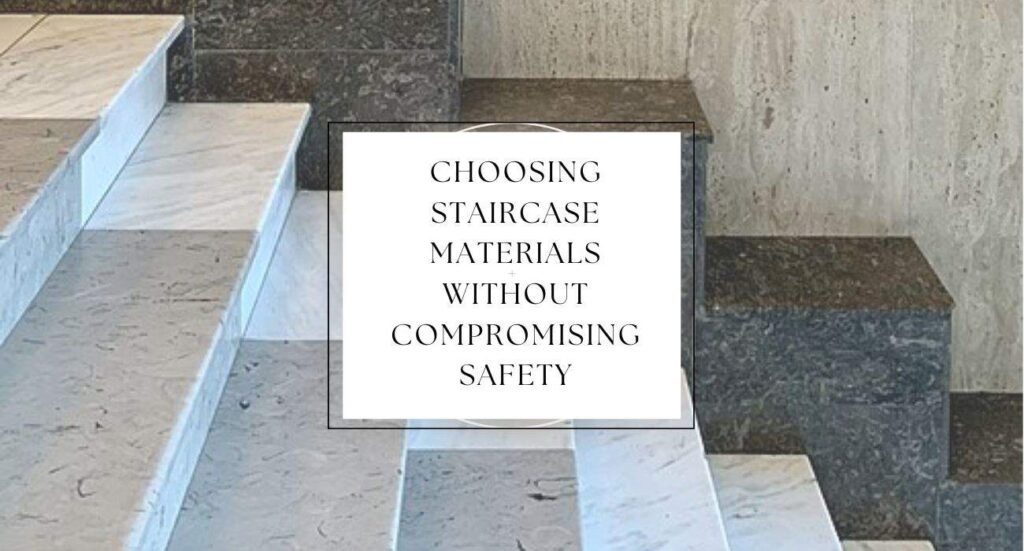

One of the most accident-prone components of any building is the staircases. There are many slips, falls, and trips on stairs, an unsuitable choice of material, wrong dimensions, or poor finish. Aesthetics may inspire staircase design; the main consideration should be safety, particularly in residential structures, businesses, hospitals, hotels, and infrastructure.

Here’s a list of best materials used for building safe staircases:

Natural Stone Materials for Staircases

- Granite

- Marble

- Slate

- Sandstone

- Limestone

Engineered Stones & Tiles for Staircases

- Vitrified Tiles

- Porcelain Tiles

- Quartz

- Composite Stone

Wood Materials for Staircases

- Teak Wood

- Oak Wood

The selection of the appropriate staircase material involves not just durability or aesthetics. It entails knowledge of surface levels, surface resistance, structural stability, dimension stability, and adherence to building standards.

Staircase Material Safety Summary Table

| Material Type | Recommended Surface Finish | Suitable Location | Safety Verdict |

Granite (e.g., Viscon White) | Ziano / Sandblasted / Flamed | Indoor & Outdoor | Highly Safe |

Marble | Leather / Sandblasted | Indoor (Low Traffic) | Conditionally Safe |

Slate | Natural Cleft | Indoor & Outdoor | Highly Safe |

Sandstone / Limestone | Natural / Sandblasted | Covered Outdoor / Indoor | Moderately Safe |

Porcelain Tiles | Structured / Outdoor Rated | Indoor & Outdoor | Highly Safe (If Certified) |

Vitrified Tiles | Matt / Anti-skid | Indoor Only | Moderately Safe |

Quartz / Composite Stone | Textured Only | Indoor Only | Conditionally Safe |

Wood (Teak, Oak) | Brushed / Grooved | Indoor Dry Areas | Moderately Safe |

| Polished Stone / Tiles | Polished | Any Staircase | Unsafe – Not Recommended |

In this article, we explain how to choose staircase materials such as granite, natural stone, tiles, engineered surfaces, and wood while prioritising safety. We also explore slip resistance, structural durability, surface finishes, and compliance with safety standards. Additionally, this guide helps homeowners, architects, and builders select materials that balance aesthetics, longevity, and user safety.

- Staircase Material Safety Summary Table

- 1. Granite (Natural Stone)

- 2. Marble (Natural Stone)

- 3. Slate (Natural Stone)

- 4. Sandstone & Limestone (Natural Stone)

- 1. Vitrified Tiles

- 2. Porcelain Tiles

- 3. Quartz & Composite Stones

- Techniques to Improve Surface Grip in Granite and Stone Stairs

- Best Surface Finishes That Are Safe for Stairs

- Basic Elements That Make a Staircase Safe

- Slip Resistance

- Strength & Stability of Staircase Materials

- Staircase Material Safety Summary Table

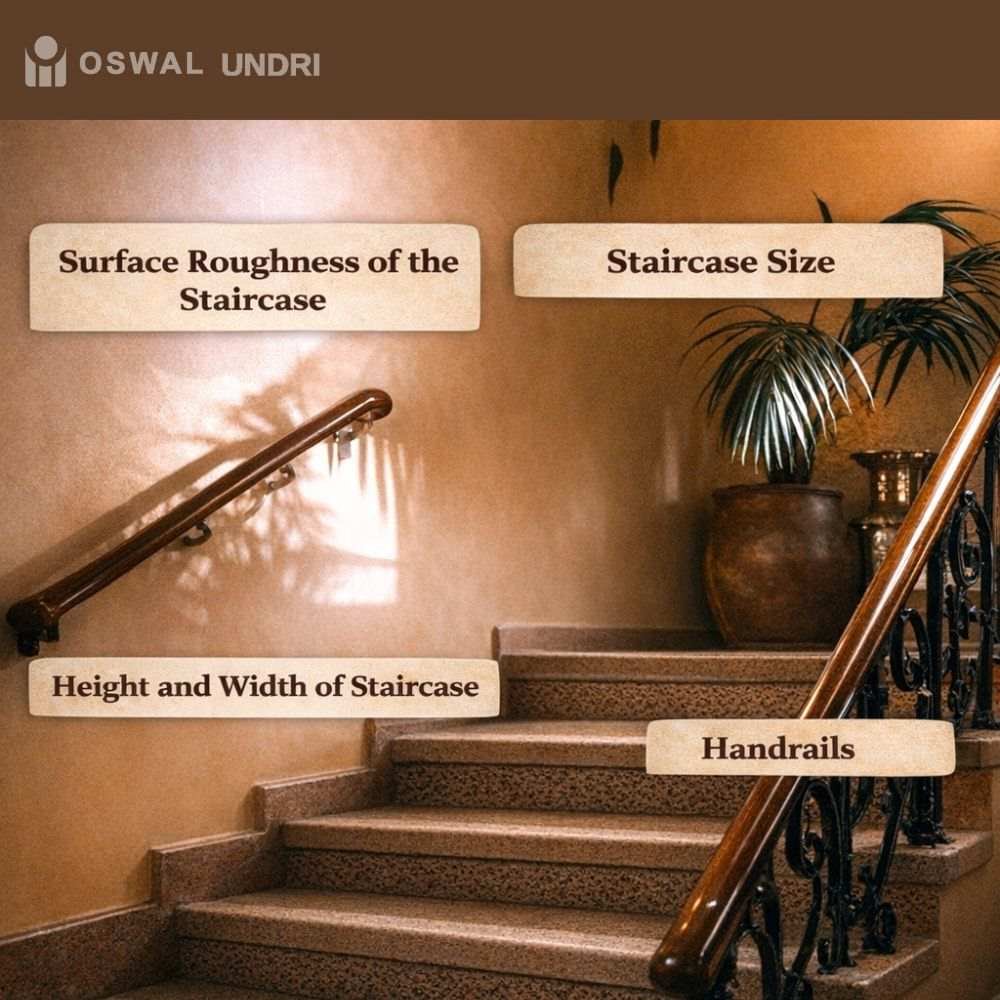

Elements That Affect Staircase Safety

1. Surface Roughness of the Staircase

Grip is directly proportional to surface roughness. Polished or smooth surfaces are risky because they can be really slippery in case of wetness. Coarser finishes give a superior foot-to-stairs friction.

2. Staircase Size

The total width of the staircase has an influence on safety and comfort. Narrow stairs heighten the chances of imbalance, particularly where heavy traffic is involved.

3. Height and Width of Staircase

One of the largest causes of falls is the irregularity of the height or depth of the step. The slightest deviation can lead to missteps.

4. Handrails

Handrails can help greatly, particularly for elderly users, children, and people with severe mobility problems. Handrails that have been poorly installed or are slippery compromise safety.

Natural Stone Materials for Staircases

1. Granite (Natural Stone)

Key Details

| Parameter | Recommendation / Details |

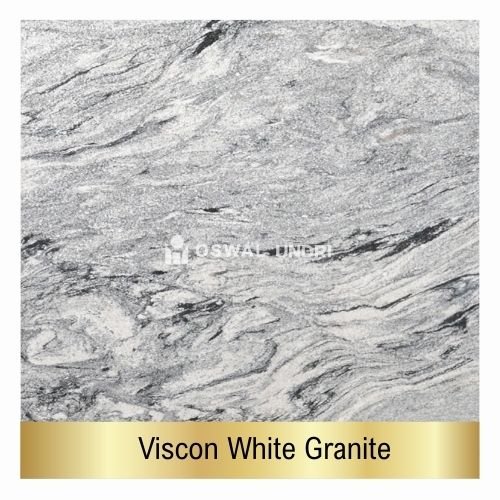

| Best granite | Viscon White Granite |

| Best surface texture | Ziano finish (indoor), Sandblasted or Flamed (outdoor) |

| Slip resistance recommended | R11 (indoor), R12 (outdoor/wet areas) |

| Thickness required | Minimum 18–20 mm |

| Edge performance | Very strong; minimal chipping when properly finished |

| Maintenance requirement | Low; periodic cleaning |

| Best use case | Residential, commercial, high-traffic staircases |

| Avoid | Polished granite on stair treads |

Reason for Selection

• Extremely high compressive strength that can be used in everyday foot traffic.

• It has low water absorption, which minimises the risk of slipping when wet.

• Superior step edge and nosing wear resistance.

• Long-term surface texture.

• Appropriate for indoor and outdoor stairs.

2. Marble (Natural Stone)

Key Details

| Parameter | Recommendation / Details |

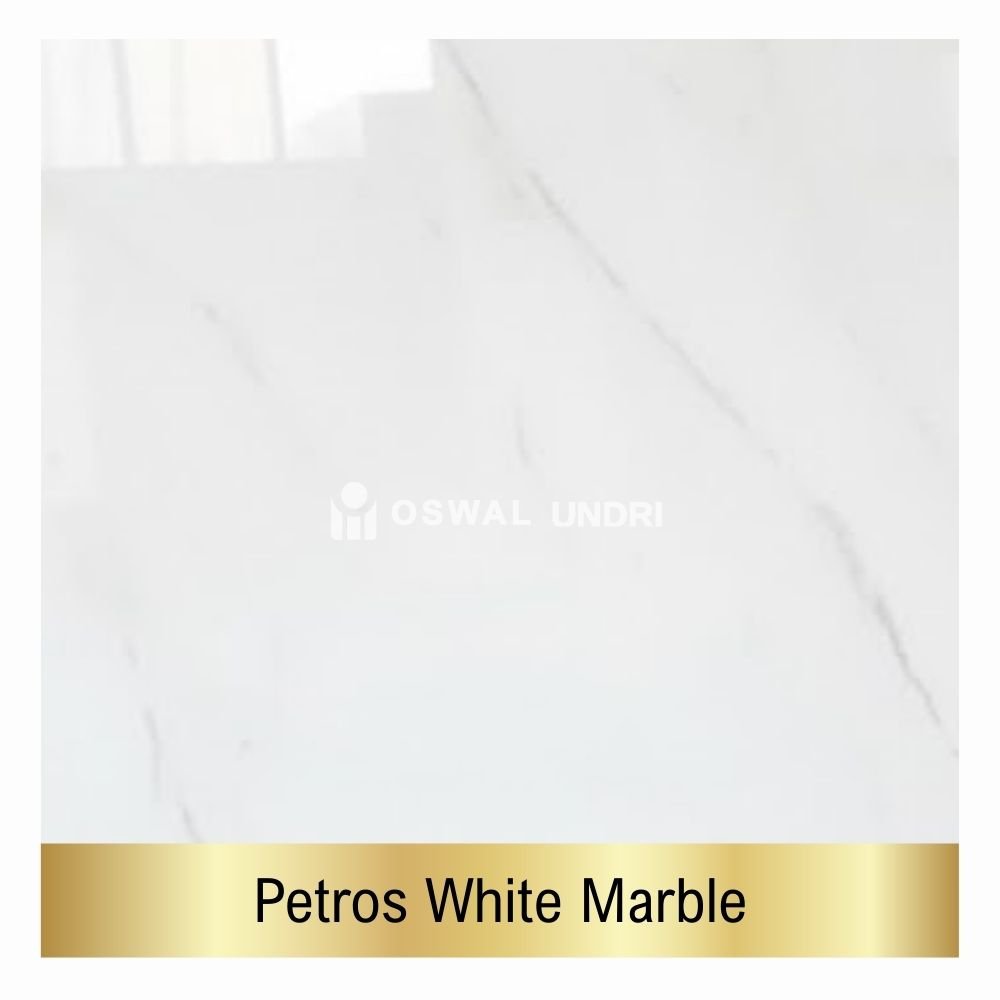

| Best marble | Hard marble varieties (e.g., Petros White Marble – textured) |

| Best surface texture | Leather finish, Sandblasted finish |

| Slip resistance recommended | R10–R11 (indoor only) |

| Thickness required | Minimum 18 mm |

| Edge performance | Moderate; prone to chipping if thin |

| Maintenance requirement | High; sealing and careful cleaning needed |

| Best use case | Low-traffic indoor residential staircases |

| Avoid | Polished marble and outdoor usage |

Reason for Selection

• Thick construction in contrast to softer decorative marbles.

• Suitable for controlled indoor environments.

• Accepts rough finishes to provide grip.

• Brightens indoor staircases visually.

• Performs well in low to moderate foot traffic.

3. Slate (Natural Stone)

Key Details

| Parameter | Recommendation / Details |

| Best slate | Natural cleft slate |

| Best surface texture | Natural cleft (unpolished) |

| Slip resistance recommended | R11 (indoor), R12 (outdoor) |

| Thickness required | Minimum 15–18 mm |

| Edge performance | Moderate; edges must be reinforced |

| Maintenance requirement | Moderate; sealing recommended |

| Best use case | Indoor and outdoor staircases, wet zones |

| Caution | Poor-quality slate may peel in layers |

Reason for Selection

• The cleft surface is naturally rough, giving high grip.

• Suitable in both wet and dry seasons.

• Excellent thermal and weather performance.

• Reduced surface treatment.

• Fits indoor and outdoor stairs.

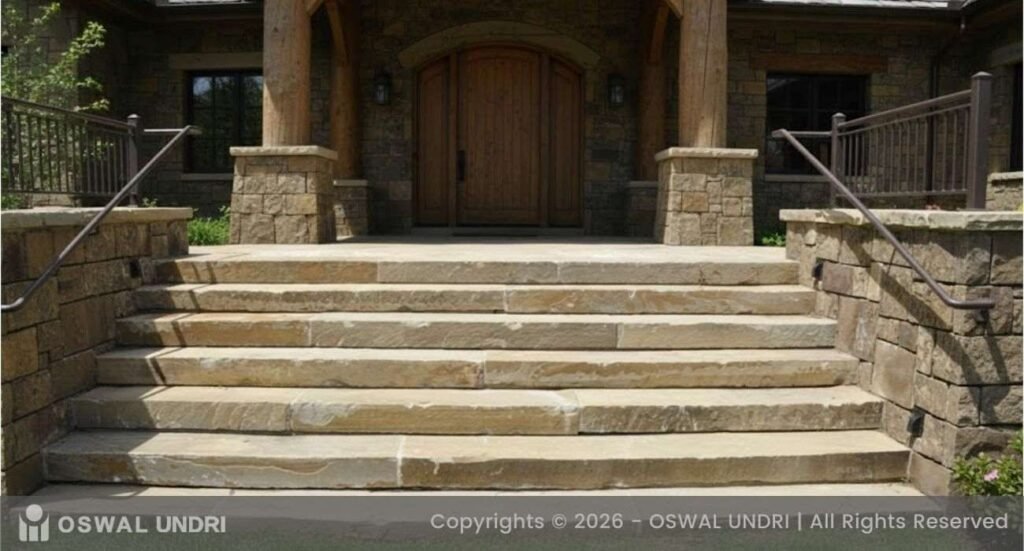

4. Sandstone & Limestone (Natural Stone)

Key Details

| Parameter | Recommendation / Details |

| Best stone type | Dense sandstone / low-porosity limestone |

| Best surface texture | Natural finish, Sandblasted finish |

| Slip resistance recommended | R11 (covered areas) |

| Thickness required | Minimum 20 mm |

| Edge performance | Weak to moderate; requires careful detailing |

| Maintenance requirement | High sealing is mandatory |

| Best use case | Covered outdoor or semi-outdoor staircases |

| Avoid | Fully exposed wet staircases |

Reason for Selection

• The textured surface provides basic slip resistance.

• Gives a more natural, earthy look.

• Suitable for covered staircases.

• Can be treated to improve grip.

• Suits where aesthetics are valued over heavy traffic.

Engineered Stones & Tiles for Staircases

1. Vitrified Tiles

Key Details

| Parameter | Recommendation / Details |

| Best tile type | Full-body vitrified tile (anti-skid grade) |

| Best surface texture | Matt / Anti-skid |

| Slip resistance recommended | R10–R11 (indoor) |

| Thickness required | Minimum 10–12 mm |

| Edge performance | Moderate; nosing recommended |

| Maintenance requirement | Low |

| Best use case | Indoor residential staircases |

| Avoid | Glossy or polished vitrified tiles |

Reason for Selection

• Homogeneous strength throughout tiles.

• Low porosity decreases absorption of water.

• Available in anti-skid variants.

• Inexpensive compared to natural stone.

• Suitable for controlled indoor environments

2. Porcelain Tiles

Key Details

| Parameter | Recommendation / Details |

| Best tile type | Outdoor-rated structured porcelain tile |

| Best surface texture | Structured/textured finish |

| Slip resistance recommended | R11 (indoor), R12 (outdoor) |

| Thickness required | Minimum 10 mm |

| Edge performance | Good with proper nosing |

| Maintenance requirement | Low |

| Best use case | Indoor and outdoor staircases |

| Requirement | Manufacturer slip-resistance certification |

Reason for Selection

• High density offers good load-bearing capacity.

• Very low water absorption.

• Available with certified slip resistance ratings.

• Long-lasting under heavy foot traffic.

• Can be used both indoors and outdoors.

3. Quartz & Composite Stones

Key Details

| Parameter | Recommendation / Details |

| Best material type | Textured quartz / composite stone |

| Best surface texture | Factory-textured (non-polished) |

| Slip resistance recommended | R10–R11 (indoor only) |

| Thickness required | Minimum 20 mm |

| Edge performance | Good with reinforced backing |

| Maintenance requirement | Low |

| Best use case | Indoor dry staircases |

| Avoid | Polished quartz on stair treads |

Reason for Selection

• Designed for uniform strength and finish.

• Low porosity increases stain resistance.

• Applicable to accurately cut stair designs.

• Minimal variation and stable material.

• Ideal in dry indoor situations.

Wood (Solid & Engineered)

Key Details

| Parameter | Recommendation / Details |

| Best wood | Teak wood, Oak wood |

| Best surface texture | Brushed, grooved, wire-cut |

| Slip resistance recommended | R10 (indoor dry areas) |

| Thickness required | As per structural design |

| Edge performance | Good when properly finished |

| Maintenance requirement | High; periodic polishing |

| Best use case | Indoor residential staircases |

| Safety add-on | Anti-skid nosing or grooves mandatory |

Reason for Selection

• Naturally warm and comfortable underfoot.

• Heavy carrying weight when supported.

• Allows grooving for slip resistance.

• Visually softens staircase design.

• Ideally suitable in dry indoor conditions.

Staircase Safety Checklist

This professional checklist will guarantee safety, life span, and authority without interfering with design before finalizing any staircase material.

1. Slip Resistance Compliance

- Ensure the material meets R11 rating for indoor stairs and R12 for outdoor or wet areas.

- Do not use polished or glossy stair treads.

2. Surface Finish Quality

- Select permanent finishes that are textured, e.g., sandblasted, flamed, or ziano.

- Avoid surface coating or chemical anti-skid treatments, which wear out with time.

3. Structural Strength & Thickness

- Ensure adequate material thickness (minimum 18–20 mm for stone).

- The material should be able to stand daily foot traffic, edge load, and impact without cracking.

4. Step Dimension Consistency

- Verify uniform riser height and tread depth across all steps.

- Deviations more than ±5 mm pose a high risk of tripping.

5. Edge Safety & Visibility

- Stair nosing must be well-finished and visible.

- Apply anti-slip grooves or differentiating edges where needed.

6. Suitability for Environment

- Match the material choice with the location, which can be indoor, outdoor, or semi-covered.

- For external stairs, check for water absorption and weather resistance

7. Handrails & Support Systems

- Assure handrails are sturdy, well-positioned, and easy to grip.

- The height must be in accordance with the building standards.

8. Standards & Certification

- Check compliance with DIN, ASTM, ISO, or National Building Code (NBC) standards.

- Ask suppliers to provide test certificates where possible.

This checklist guarantees that your staircase is not only aesthetically attractive but also secure, in compliance, and durable.

Techniques to Improve Surface Grip in Granite and Stone Stairs

- Sandblasting – Abrasive particles are shot at high speed onto the stone surface to produce an even or rough texture, which provides better grip and stands the test of time on indoor and outdoor stairs.

- Flaming – The surface of high-temperature flames is applied to the stone, with small cracks, creating a coarse texture that makes the stone less slippery, particularly on outdoor staircases.

- Ziano Finish – A mechanical texturing furnished through the use of diamond abrasives, which form a small, matte finish on granite, offering both aesthetics and resistance to interior sliding.

- Bush Hammering – Specialised hammers form a pitted and rough surface on rock through repeated blows, improving friction but preserving structural integrity to stair steps.

- Grooving – Shallow grooves or straight cuts along the direction of treading are cut to provide friction, particularly at high-foot traffic or wet areas.

- Thermal or Acid Etching – Thermal processing or mild acid application is used to rough the surface at a microscopic scale and raise the coefficient of friction without changing overall appearance.

Best Surface Finishes That Are Safe for Stairs

| Finish Type | Method / Process | Slip Resistance | Suitable For | Additional Details / Notes |

| Sandblasted | High-pressure abrasive blasting of the stone surface | R11–R12 | Indoor & outdoor stairs | • Generates a homogeneous micro-roughness to enhance grip. • Long-lasting finish, which is not easily worn out. • Minimises slipperiness in the wet state. • Granite, marble, sandstone, and limestone. |

| Ziano Finish | Controlled mechanical texturing with diamond-tipped tools | R11 | Premium indoor stairs | • Smooth but with a little textured surface for elegance and safety • Retains a sophisticated outlook as well as offering anti-slip capabilities. • Ideal in high-end residential or commercial staircases. • Applied usually on dense marbles and granite. |

| Flamed / Thermal Finish | The stone surface is exposed to high-temperature flame, causing micro-fractures | R12–R13 | Outdoor & wet stairs | • Gives it a naturally rough surface that is effective in a wet environment. • Highly anti-slip with a textured surface. • Fits well in outdoor granite steps, around pools, and general pedestrian steps. • Low maintenance needed; weather-resistance. |

Understanding Safety in Staircases

Basic Elements That Make a Staircase Safe

Step Height and Depth

- Riser height: Ideally 150–175 mm

- Tread depth: Minimum 250–300 mm

- Variation should not exceed ±5 mm

Inconsistent steps cause discontinuity in walking and pose a serious risk of falls.

Clear Step Edges and Visible Stair Ends

- The stair nosing should be prominent.

- Visibility is enhanced by the use of anti-skid strips or contrasting edges.

- This is of particular interest to elderly users.

Importance of Sturdy Handrails

- Handrails should be able to withstand sideways or lateral loads.

- Recommended height: 850–950 mm

- Should not be difficult to hold.

Role of Proper Lighting on Staircases

- No shadows, even lighting.

- No glare on glossy surfaces

- There should be visible step edges.

Slip Resistance

Why Some Materials Are Slippery, and Others Are Not

Slipperiness depends on:

- Surface texture

- Presence of water or dust

- The hardness and degree of polish of the material.

The surface is highly polished to minimise friction.

Difference Between Dry and Wet Stair Conditions

- Dry stairs can be considered safe and unsafe when wet.

- Outdoor stairs must always be designed for wet conditions.

How Surface Finish Affects Grip

- Polished offers a poor grip

- Textured / flamed/sandblasted offers a better grip

Common Mistakes That Increase Slipping Risk

- Steps made of polished marble or granite

- Applying glossy sealers

- Ignoring wet conditions

- No nosing or anti-skid treatment

Strength & Stability of Staircase Materials

Why Stair Materials Must Handle Daily Load

Staircases experience:

- Concentrated foot loads

- Repeated impact

- Edge stress on nosing

Weak materials fracture at step edges.

Indoor vs Outdoor Staircase Requirements

| Factor | Indoor | Outdoor |

| Weather resistance | Low | High |

| Slip resistance | R11 | R12 minimum |

| Strength | Moderate | High |

| Water absorption | Less critical | Very important |

How Poor Material Choice Leads to Cracks or Breakage

- Soft stones wear quickly

- Thin slabs crack at edges

- Breakage is possible due to poor backing support

Matching Material Type With Staircase Structure

- Cantilever stairs require strong stone.

- The RCC stairs permit broader material selections.

Staircase Material Safety Summary Table

| Material Type | Recommended Surface Finish | Suitable Location | Safety Verdict |

Granite (e.g., Viscon White) | Ziano / Sandblasted / Flamed | Indoor & Outdoor | Highly Safe |

Marble | Leather / Sandblasted | Indoor (Low Traffic) | Conditionally Safe |

Slate | Natural Cleft | Indoor & Outdoor | Highly Safe |

Sandstone / Limestone | Natural / Sandblasted | Covered Outdoor / Indoor | Moderately Safe |

Porcelain Tiles | Structured / Outdoor Rated | Indoor & Outdoor | Highly Safe (If Certified) |

Vitrified Tiles | Matt / Anti-skid | Indoor Only | Moderately Safe |

Quartz / Composite Stone | Textured Only | Indoor Only | Conditionally Safe |

Wood (Teak, Oak) | Brushed / Grooved | Indoor Dry Areas | Moderately Safe |

| Polished Stone / Tiles | Polished | Any Staircase | Unsafe – Not Recommended |

FAQs

Q1. Which staircase materials have the safest surface finish?

Sandblasted finishes, flamed finishes, and Ziano finishes are more slip-resistant. These finishes produce a permanent roughness of the surface that enhances grip. Stair treads should not be of a polished or glossy finish.

Q2. What is the recommended rating of the slip resistance?

Staircases within a building must have a minimum slip rating of R11, whereas outdoors or wet staircases must be R12 or higher. In dry and wet conditions, these ratings ensure that there is sufficient grip.

Q3. Will granite be an effective staircase material?

Well, with a textured surface, granite is a safe and strong building material for stairs. It is an excellent choice as it has a high load-bearing capacity, low water absorption, and high durability for daily use.

Q4. Can marble be utilised to construct a staircase?

Indoor stairs with low to moderate foot traffic can be finished with marble, provided that a non-polished type is taken. Marble is too smooth to be used on the stairs, particularly where it may be exposed to water.

Q5. Is tile safe for a staircase?

The safety of the tiles is possible only when the tiles are anti-slip or designed to be used on stairs. There should be no glossy vitrified or polished tiles on the staircases because they are very slippery.

Q6. What is the significance of a constant step height of stairs?

Equal riser height and tread depth contribute to the walking rhythm and balance. The smallest differences between steps may lead to missteps and the possibility of falls, particularly amongst geriatric users.

Key Takeaways

- Staircase safety mainly depends on slip resistance, surface finish, and structural strength of the material.

- Textured finishes such as sandblasted, flamed, or Ziano significantly improve grip and reduce slipping risks.

- Granite, porcelain tiles, and natural cleft slate are among the safest materials for both indoor and outdoor staircases.

- Polished surfaces, thin slabs, and uncertified materials increase accident risks and should be avoided on stair treads.

- Proper step dimensions, sturdy handrails, and compliance with safety standards are equally important as material selection.

Get a free consultation, expert guidance, and a detailed quote tailored to your project needs.